The expanded metal is made out of mild, pre-galvanized and stainless steel or aluminum sheets. The sheets are cut and stretched. That is how the diamond shaped meshes are formed. Thanks to this technology they are strong and durable under the environmental challenges unlike woven or welded meshes. Also, when the meshes are being produced the sheets are stretched several times so there is no material lost during the process of production. Because of the low production price the cost of expanded metal is lower than the alternatives. These meshes guarantee the free flow of air, liquids and light. Also they provide durability and an esthetic look.

Stainless Steel

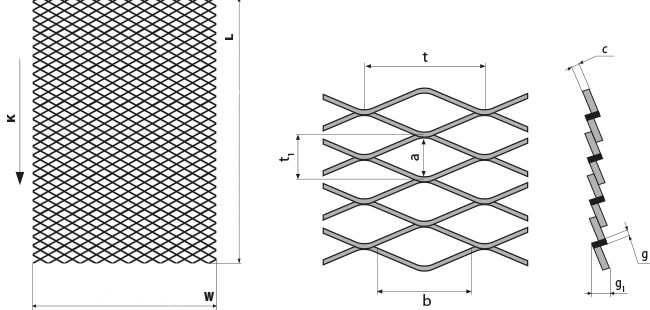

t – width of pitch

t1 – length of pitch

a – height of mesh

b – width of mesh

c – strand width

g – thickness of raw material

g1 – thickness of expanded metal mesh

L – lenght of expanded metal sheet

W – width of expanded metal sheet

K – direction of production process

Main parameters of expanded metal

Mild Steel

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] MILD STEEL | max. width [mm] | strand width “c“value +/- 0.3 mm |

| 1.2×2 | 2×4 | 0,5 | 500 | 0,5-0,6 |

| 2×3 | 3×6 | 0,5-1 | 1000 | 0,5-1,2 |

| 4,5×7 | 6,4×11 | 0,5-2 | 1250 | 0,5-2 |

| 4.5×7.5 | 6×10 | 0,5-1 | 1000 | 0,5-1,5 |

| 4.5×9 | 6×12 | 0,5-2 | 1250 | 0,5-2 |

| 4.5×12 | 6×16 | 0,5-1,2 | 1000 | 0,5-1,2 |

| 4.5×24 | 7×29 | 0,5-1 | 1000 | 0,5-1,2 |

| 5,5×9,5 | 7×12,5 | 0,5-1,5 | 550 | 0,5-1,5 |

| 6×11 | 7,5×14 | 0,5-2 | 1250 | 0,5-2 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] MILD STEEL | max. width [mm] | strand width “c“value +/- 0.3 mm |

| 6×30 | 10×42 | 0,5-2 | 1250 | 0,5-2 |

| 7×13,5 | 10×18 | 0,5-2 | 1000 | 0,5-2,5 |

| 7×15 | 10×20 | 0,5-2 | 1250 | 0,5-2 |

| 7×24 | 10×30 | 0,5-2 | 1500 | 0,5-2,5 |

| 7×42 | 10×50 | 0,5-1,5 | 1000 | 0,5-2 |

| 8,5×13,5 | 12×18 | 0,5-2 | 1000 | 0,5-2,5 |

| 10×16 | 12×20 | 0,5-2 | 1250 | 0,5-2,5 |

| 10×42 | 12.5×50 | 0,5-2 | 1250 | ,5-2,5 |

| 11×16,5 | 12,5×20 | 0,5-1,5 | 1250 | 0,5-2,5 |

| 12×42 | 15×50 | 0,5-1,5 | 1250 | 0,5-3 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] MILD STEEL | max. width [mm] | strand width “c“value +/- 0.3 mm |

| 12×42 | 15×50 | 0,5-2 | 1250 | 0,5-3 |

| 14×25 | 16.5×30 | 0,5-3 | 1500 | 0,5-3,5 |

| 14×37 | 21×50 | 0,5-3* | 1250 | 0,5-3 |

| 14×52 | 23×62,5 | 0,5-3 | 1500 | 0,5-3 |

| 17×52 | 20×62 | 0,5-3 | 1250 | 0,5-5 |

| 17×52 | 20×62,5 | 0,5-3 | 1500 | 0,5-5 |

| 18×42 | 22,5×50 | 0,5-3 | 1500 | 0,5-5 |

| 21×65 | 25×75 | 0,5-4 | 1500 | 0,5-5 |

| 33×88 | 37,5×100 | 0,5-4 | 1500 | 0,5-12** |

Pre-Galvanized

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] PRE-GALVANIZED | max. width [mm] | strand width”c” value +/- 0.3 mm |

| 1.2×2 | 2×4 | 0,5 | 500 | 0,5-0,6 |

| 2×3 | 3×6 | 0,5-1 | 1000 | 0,5-1,2 |

| 4,5×7 | 6,4×11 | 0,5-1 | 1250 | 0,5-2 |

| 4.5×7.5 | 6×10 | 0,5-1 | 1000 | 0,5-1,5 |

| 4.5×9 | 6×12 | 0,5-1 | 1250 | 0,5-2 |

| 4.5×12 | 6×16 | 0,5-1 | 1000 | 0,5-1,2 |

| 4.5×24 | 7×29 | 0,5-1 | 1000 | 0,5-1,2 |

| 5,5×9,5 | 7×12,5 | 0,5-1,5 | 550 | 0,5-1,5 |

| 6×11 | 7,5×14 | 0,5-1,5 | 1250 | 0,5-2 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] PRE-GALVANIZED | max. width [mm] | strand width “c” value +/- 0.3 mm |

| 6×30 | 10×42 | 0,5-1,5 | 1250 | 0,5-2 |

| 7×13,5 | 10×18 | 0,5-1,5 | 1000 | 0,5-2,5 |

| 7×15 | 10×20 | 0,5-2 | 1250 | 0,5-2 |

| 7×24 | 10×30 | 0,5-2 | 1500 | 0,5-2,5 |

| 7×42 | 10×50 | 0,5-1,5 | 1000 | 0,5-2 |

| 8,5×13,5 | 12×18 | 0,5-1,5 | 1000 | 0,5-2,5 |

| 10×16 | 12×20 | 0,5-2 | 1250 | 0,5-2,5 |

| 10×42 | 12.5×50 | 0,5-2 | 1250 | 0,5-2,5 |

| 11×16,5 | 12,5×20 | 0,5-1,5 | 1250 | 0,5-2,5 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] PRE-GALVANIZED | max. width [mm] | strand width “c” value +/- 0.3 mm |

| 12×42 | 15×50 | 0,5-1,5 | 1250 | 0,5-3 |

| 14×25 | 16.5×30 | 0,5-2 | 1500 | 0,5-3,5 |

| 14×37 | 21×50 | 0,5-2 | 1250 | 0,5-3 |

| 14×52 | 23×62,5 | 0,5-2 | 1500 | 0,5-3 |

| 17×52 | 20×62 | 0,5-2 | 1250 | 0,5-5 |

| 17×52 | 20×62,5 | 0,5-2 | 1500 | 0,5-5 |

| 18×42 | 22,5×50 | 0,5-2 | 1500 | 0,5-5 |

| 21×65 | 25×75 | 0,5-2 | 1500 | 0,5-5 |

| 33×88 | 37,5×100 | 0,5-2 | 1500 | 0,5-5 |

Aluminium

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] ALUMINIUM | max. width [mm] | strand width “c“value +/- 0.3 mm |

| 1.2×2 | 2×4 | 0,5 | 500 | 0,5-0,6 |

| 2×3 | 3×6 | 0,5-1 | 1000 | 0,5-1,2 |

| 4,5×7 | 6,4×11 | 0,5-2,5 | 1250 | 0,5-2 |

| 4.5×7.5 | 6×10 | 0,5-1 | 1000 | 0,5-1,5 |

| 4.5×9 | 6×12 | 0,5-2 | 1250 | 0,5-2 |

| 4.5×12 | 6×16 | 0,5-1,5 | 1000 | 0,5-1,2 |

| 4.5×24 | 7×29 | 0,5-1,5 | 1000 | 0,5-1,2 |

| 5,5×9,5 | 7×12,5 | 0,5-4 | 550 | 0,5-1,5 |

| 6×11 | 7,5×14 | 0,5-2 | 1250 | 0,5-2 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] ALUMINIUM | max. width [mm] | strand width “c“value +/- 0.3 mm |

| 6×30 | 10×42 | 0,5-2,5 | 1250 | 0,5-2 |

| 7×13,5 | 10×18 | 0,5-2 | 1000 | 0,5-2,5 |

| 7×15 | 10×20 | 0,5-2 | 1250 | 0,5-2 |

| 7×24 | 10×30 | 0,5-1,5 | 1500 | 0,5-2,5 |

| 7×42 | 10×50 | 0,5-2,5 | 1000 | 0,5-2 |

| 8,5×13,5 | 12×18 | 0,5-2,5 | 1000 | 0,5-2,5 |

| 10×16 | 12×20 | 0,5-2 | 1250 | 0,5-2,5 |

| 10×42 | 12.5×50 | 0,5-2 | 1250 | 0,5-2,5 |

| 11×16,5 | 12,5×20 | 0,5-2 | 1250 | 0,5-2,5 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] ALUMINIUM | max. width [mm] | strand width “c“value +/- 0.3 mm |

| 12×42 | 15×50 | 0,5-1,5 | 1250 | 0,5-3 |

| 14×25 | 16.5×30 | 0,5-3 | 1500 | 0,5-3,5 |

| 14×37 | 21×50 | 0,5-2,5 | 1250 | 0,5-3 |

| 14×52 | 23×62,5 | 0,5-4 | 1500 | 0,5-3 |

| 17×52 | 20×62 | 0,5-4 | 1250 | 0,5-5 |

| 17×52 | 20×62,5 | 0,5-4 | 1500 | 0,5-5 |

| 18×42 | 22,5×50 | 0,5-4 | 1500 | 0,5-5 |

| 21×65 | 25×75 | 0,5-4 | 1500 | 0,5-5 |

| 33×88 | 37,5×100 | 0,5-4 | 1500 | 0,5-15*** |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] 0H18N9 (STAINLESS STEEL) | max. width [mm] | strand width “c” value +/- 0.3 mm |

| 2×3 | 3×6 | 0,5-0,8 | 600 | 0,5-1,2 |

| 4,5×7 | 6,4×11 | 0,5-1 | 1250 | 0,5-2 |

| 4.5×7.5 | 6×10 | 0,5-1 | 1000 | 0,5-1,5 |

| 4.5×9 | 6×12 | 0,5-1 | 1000 | 0,5-2 |

| 4.5×12 | 6×16 | 0,5-1 | 1000 | 0,5-1,2 |

| 4.5×24 | 7×29 | 0,5-1 | 1000 | 0,5-1,2 |

| 5,5×9,5 | 7×12,5 | 0,5-1,5 | 550 | 0,5-1,5 |

| 6×11 | 7,5×14 | 0,5-1,5 | 1000 | 0,5-2 |

| 6×30 | 10×42 | 0,5-1 | 1250 | 0,5-2 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] 0H18N9 (STAINLESS STEEL) | max. width [mm] | strand width “c” value +/- 0.3 mm |

| 7×13,5 | 10×18 | 0,5-2 | 1000 | 0,5-2,5 |

| 7×15 | 10×20 | 0,5-1,5 | 1200 | 0,5-2 |

| 7×24 | 10×30 | 0,5-2 | 1500 | 0,5-2,5 |

| 7×42 | 10×50 | 0,5-1,5 | 1000 | 0,5-2 |

| 8,5×13,5 | 12×18 | 0,5-1,5 | 1000 | 0,5-2,5 |

| 10×16 | 12×20 | 0,5-1,5 | 1250 | 0,5-2,5 |

| 10×42 | 12.5×50 | 0,5-2 | 1250 | 0,5-2,5 |

| 11×16,5 | 12,5×20 | 0,5-1 | 1250 | 0,5-2,5 |

| axb [mm] | t1xt [mm] | thickness of material “g” [mm] 0H18N9 (STAINLESS STEEL) | max. width [mm] | strand width “c” value +/- 0.3 mm |

| 14×25 | 16.5×30 | 0,5-2 | 1250 | 0,5-3,5 |

| 14×37 | 21×50 | 0,5-2 | 1250 | 0,5-3 |

| 14×52 | 23×62,5 | 0,5-3 | 1500 | 0,5-3 |

| 17×52 | 20×62 | 0,5-3 | 1250 | 0,5-5 |

| 17×52 | 20×62,5 | 0,5-3 | 1500 | 0,5-5 |

| 18×42 | 22,5×50 | 0,5-2 | 1500 | 0,5-5 |

| 21×65 | 25×75 | 0,5-3 | 1500 | 0,5-5 |

| 33×88 | 37,5×100 | 0,5-3 | 1500 | 0,5-5 |

* for 3mm thickness max. width is 1000mm;

** up to 12mm strand width only for thickness 2mm, max. width 1250mm;

*** up to 15mm strand width only for thickness 2mm, max. width 1250mm.

Values of (a) and (b) are adjustable, depend on raw material thickness, strand width (c) , cutting tool.

(a) and (b) in above tables are theoretical.

Upon client’s request expanded metal sheets may be flattened. It can only be done from a new production order.

For the dimensions of nets produced with standard metal sheets width’s (1000, 1250 or 1500mm) tolerance (W) is +/-8mm. For the nets without final cutting length tolerance (L) is +100mm.

For nets made with thickness of material up to g=2mm – it can be offerd in a coil.

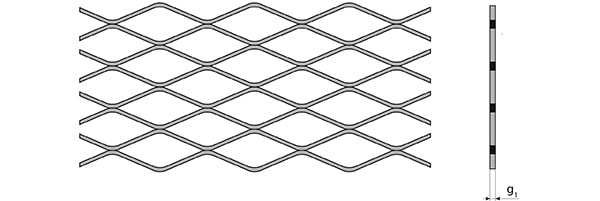

Expanded metal

g1 – thickness of expanded metal*

* (g1) thickness for the meshes without flattened option, (g1) this parameter depends on strand width “c“

Expanded metal mesh (flattened version)

g1 – thickness of expanded metal*

* it is assumed that (g1) after the flattening process equals (g) (thickness of raw material)

Expanded metal meshes can be flattened to the thickness of raw material (g). Maximum thickness is 3mm, the width (W) up to 1500mm.

Expanded metal in a coil